We are the manufacturer, can be continuous supply for at least 20 years !!

>>>> NO MOQ

>>>> Free Sample

>>>> Fast Delivery

>>>> Any information can consult us.

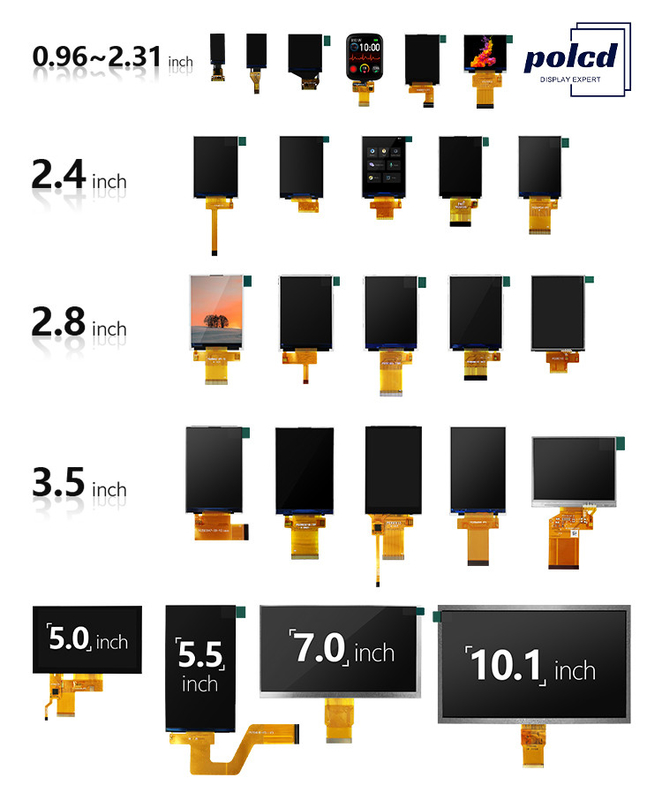

What is TFT LCD ?

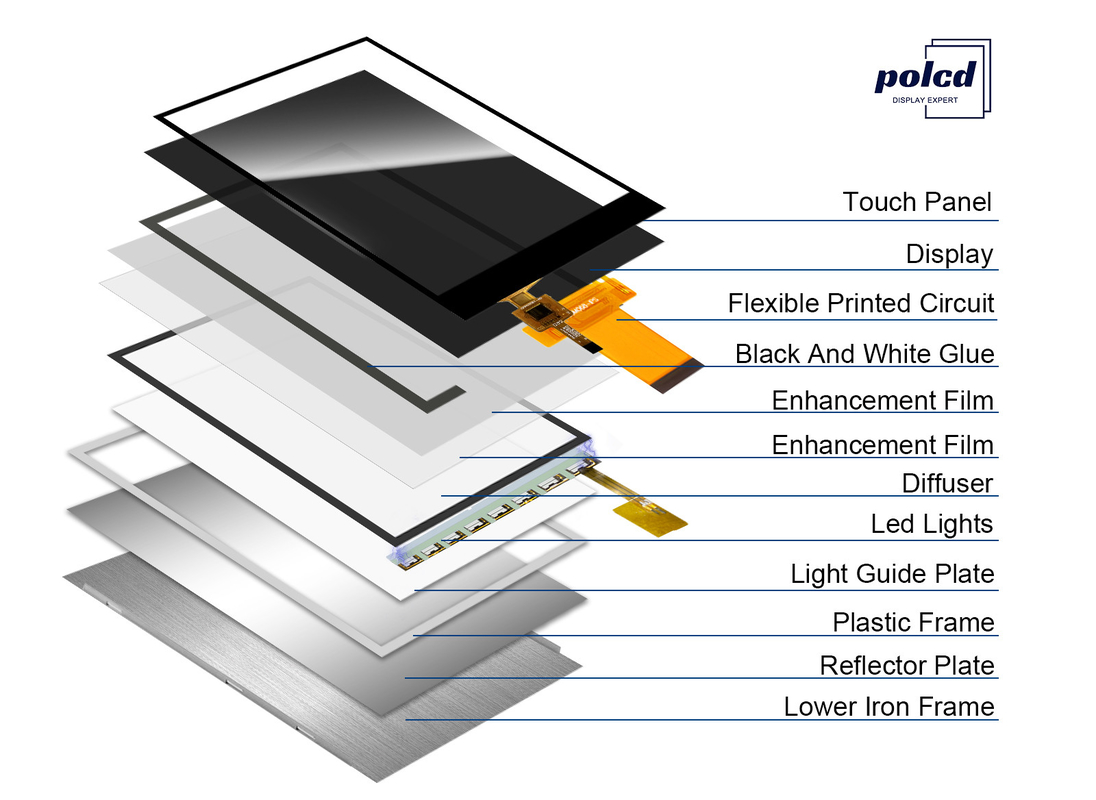

A TFT LCD module (Thin-Film-Transistor Liquid Crystal Display module) is a type of display module that uses thin-film-transistor (TFT) technology to improve the image quality and response time of the display. It's composed of different layers, including a backlight layer, a color filter layer, a TFT layer, and a glass substrate layer. TFT LCD displays are ideal for a variety of electronic devices due to their high resolution, fast refresh rate, and low power consumption.

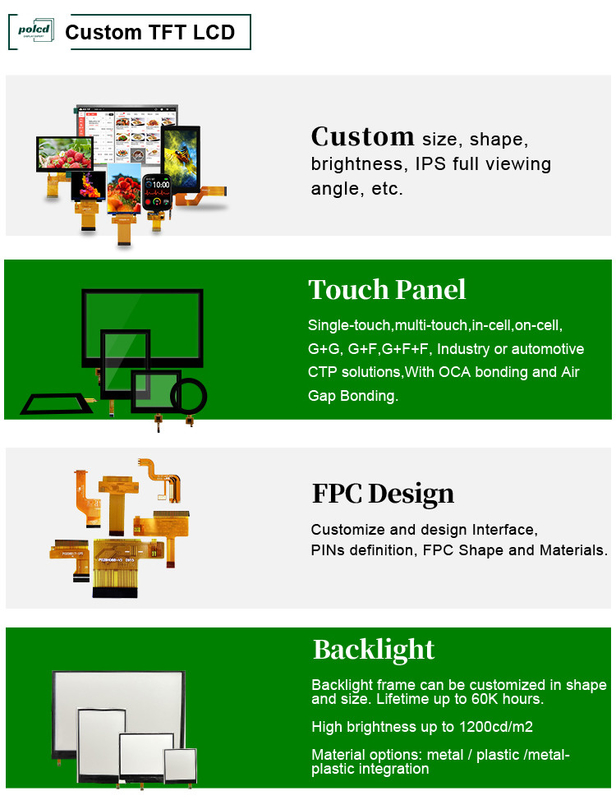

R&D, Design and Customization

Customized service are acceptable, such as LCD size, touch panel, backlight, brightness, view angle, FPC shape and materials and so on. From software development, data analysis, hardware design and prototyping, our engineer team has 15 years of experience in developing and implementing innovative technologies to meet growing market demands.

Application

Our products are widely used in medical equipment, industrial instruments, telecommunication terminals, smart home and smart wearable device, aviation, automotive, military, retail, gaming and other fields.

Custom Touch Panel

Our TFT displays can be customized with capacitive or resistive touch screens, with glass or acrylic custom panels. In addition, we can also customize blue light filters to protect users' eyes from harmful blue light radiation. The touch panel offers single and multi-touch options. Single-point touch only needs to respond to one touch point, while multi-touch screen needs to respond to the position and action of multiple touch points at the same time, so more advanced touch sensor technology and higher processing power are required to achieve faster response speed.

| Model |

Size |

Resolution |

Driver IC |

Brightness

(cd/m2)

|

Interface

(Optional)

|

| P096H001 |

0.96 |

80x160 |

ST7735S |

400 |

SPI / MCU / RGB |

| P114H002 |

1.14 |

135x240 |

ST7789V |

550 |

SPI / MCU / RGB |

| P128H002-IPS |

1.28 |

240x240 |

GC9A01 |

300 |

SPI / MCU / RGB |

| P133H002 |

1.33 |

240x240 |

ST7789V |

350 |

SPI / MCU / RGB |

| P169H002-CTP |

1.69 |

240x280 |

ST7789V |

350 |

SPI / MCU / RGB |

| P177C011 |

1.77 |

128x160 |

ST7262 |

300 |

SPI / MCU / RGB |

| P019B01-8 |

1.9 |

170x320 |

ST7789P3 |

600 |

SPI / MCU / RGB |

| P020H017-IPS |

2 |

240x320 |

ST7789V |

300 |

SPI / MCU / RGB |

| P021B001-IPS |

2.1 |

480x480 |

ST7701S |

300 |

SPI / MCU/ RGB/ MIPI |

| P022H002 |

2.2 |

240x320 |

ST7789V |

260 |

SPI / MCU / RGB |

| P023H022 |

2.31 |

320x240 |

ILI9342C |

300 |

SPI / MCU / RGB |

| P024C009 |

2.4 |

240x320 |

ILI9341V |

350 |

SPI / MCU / RGB |

| P027-40-V2 |

2.7 |

960x240 |

ILI8191 |

280 |

SPI / MCU / RGB |

| P028H042 |

2.8 |

240x320 |

ILI9341V |

300 |

SPI / MCU / RGB |

| P030H005-IPS |

3 |

268x800 |

ST7701S |

700 |

SPI / MCU / RGB |

| P032H013 |

3.2 |

240x320 |

ST7789V |

300 |

SPI / MCU / RGB |

| P032010A |

320x820 |

ST7701S |

300 |

SPI / MCU / RGB |

| P035C013 |

3.5 |

320x480 |

ILI9488 |

450 |

SPI / MCU / RGB |

| P0397H13-24-V5 |

3.97 |

480x800 |

NT35510 |

300 |

SPI / MCU / RGB |

| P040H001-CTP |

4.0 |

480x480 |

ST7701S |

350 |

SPI / MCU / RGB |

| P043B018 |

4.3 |

800x480 |

ST7262E43 |

300 |

SPI / MCU / RGB |

| P050B028-IPS |

5.0 |

800x480 |

ST7262 |

300 |

SPI / MCU / RGB |

| P0T107HS500-V0 |

720x1280 |

HX8394-F |

500 |

SPI / MCU/ RGB/ MIPI |

| P055H018-IPS-V3 |

5.5 |

720x1280 |

ST7703 |

300 |

SPI / MCU/ RGB/ MIPI |

| P070C012 |

7.0 |

800x480 |

1*EK9716BD4

1*EK73002AB2

|

300 |

SPI / MCU/ RGB |

| P10150UX-V01 |

10.1 |

1024x600 |

EK79001 |

300 |

SPI / MCU/ RGB |

Free Service:

1. Free Connectors for Sample Order.

2. 50% Discount for Tooling Charge.

3. Free Modification for Tooling of CTP / FPC / Backlight.

4. Free Tooling for Order ≥3000pcs Within 1 Year VIP.

5. Free Tooling for FPC.

6. Free Samples for Standard Products.

7. Free Testing Board for New Projects.

8. Half Tooling Fee for Customizing Backlight / CTP.

The brightness of TFT Screen is usually measured in (cd/m²) or nits. Our displays use advanced technology and high-quality components to deliver excellent image quality and clarity even at high brightness levels, which can also be adjusted to suit different lighting conditions. Examples include bright sunlight or dimly lit environments. This design allows our customers to customize brightness levels for their uniquely sized displays and ensures content is visible and readable in all conditions.

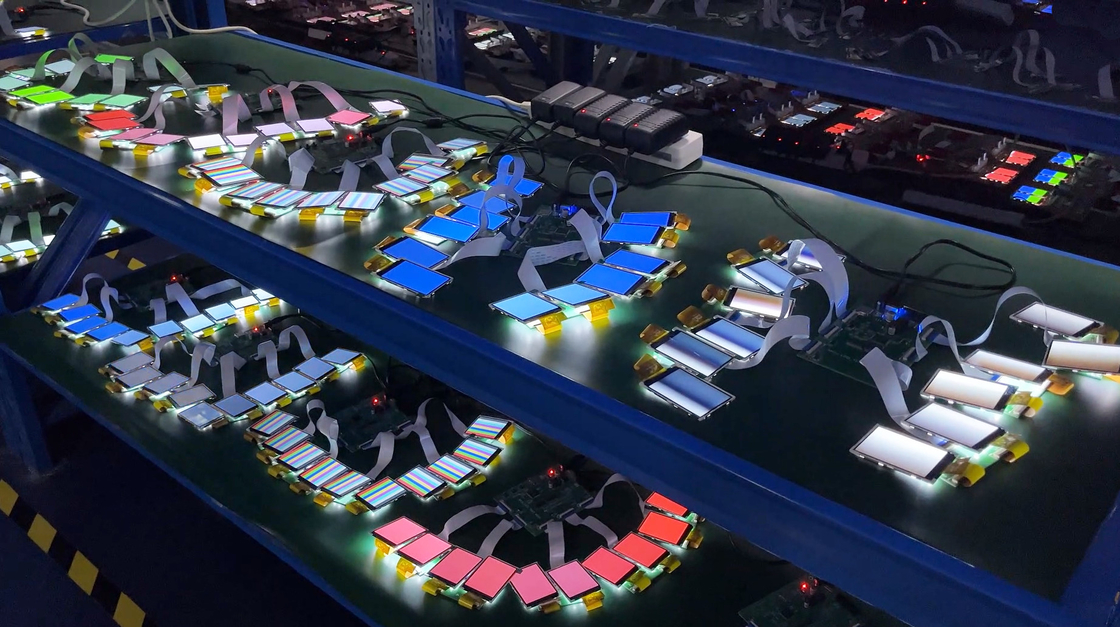

Strict Quality Inspection

Polcd's LCD screens can be used in the aerospace industry because we have veryhigh quality requirements. The raw materials are purchased from high-end brands. Professional testing equipment will be used for testing every step in the period of production. The most important thing is that before the products shipped, we can do more and more precise aging tests than those in the same industry.

Factory Strength

The production line of our factory is usually composed of multiple production units, each unit includes various advanced production equipment and automatic control system, adopts refined production process and strict quality control measures to ensure high efficiency and high quality production, to meet the growth of market demand and the continuous development of technology.

Our R&D department has extensive expertise and experience to conduct innovative research and development utilizing the latest technologies and tools. Our goal is to continuously improve the performance and functionality of TFT screen display in terms of color, contrast, and energy efficiency to meet growing market demands.

TFT LCD Screen is a widely used display technology in modern electronic devices, which offers high definition, fast response time, and low power consumption. To produce TFT module, highly precise production equipment and complex manufacturing processes are required. Therefore, TFT LCD factories usually have advanced equipment and technology to ensure high-quality and high output. These factories involve multiple production steps, including cleaning, cutting, and coating of glass substrates, deposition, photolithography, and etching of thin films, and utilize automated control systems to ensure production stability and consistency.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!